TIZ IMPLEMENTS

Jako firma inżynieringowa oferujemy kompleksowe rozwiązania w zakresie obróbki skrawaniem

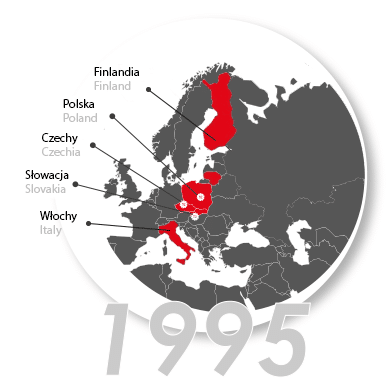

Na polskim rynku działamy od 1995 roku. Nasza firma posiada rozległą sieć dystrybutorów na terenie całej Polski, Czech, Słowacji. W przyszłości planujemy rozszerzyć naszą działalność na inne kraje.

Trendy rynkowe

Systemy TIZ:

Rynek narzędzi skrawających zaczyna przypominać rynek AGD lub RTV. Producenci prześcigają się wymyślaniu coraz to nowszych nazw dla produktów o identycznych właściwościach. Coraz trudniej jest odnaleźć wartościowe i naprawdę innowacyjne produkty. Na rynku narzędzi skrawających również odnajdziemy wiele podobnych produktów różnych firm. Aby dowiedzieć się, które z nich są najlepsze w określonych warunkach, potrzebne jest przeprowadzenie testów. Systemy TIZ rozwiązują ten problem.

25 lat na rynku

Jako firma inżynieringowa oferujemy kompleksowe rozwiązania w zakresie obróbki skrawaniem. W swojej działalności skupiamy się nie tylko na produkcji i dystrybucji wysokowydajnych narzędzi skrawających, ale także na profesjonalnym doradztwie technicznym w zakresie obróbki skrawaniem i prawidłowego doboru narzędzi. Ponadto zajmujemy się wdrażaniem nowoczesnych rozwiązań przemysłowych.

TOCZENIE

Posiadamy szeroką gamę narzędzi oraz płytek wieloostrzowych wykorzystywanych do wszystkich typów operacji toczenia. Połączenie węglików oraz powłok ochronnych pozwala na uzyskanie maksymalnej żywotności oraz wydajności narzędzi.

FREZOWANIE

Narzędzia do frezowania to m.in. frezy walcowe, kuliste, torusowe, tarczowe, teowe oraz stożkowe. Posiadamy bogatą ofertę narzędzi powlekanych, które są zalecane do obróbki form odlewniczych lub wtryskowych, matryc, stempli oraz detali w przemyśle samochodowym i lotniczym.

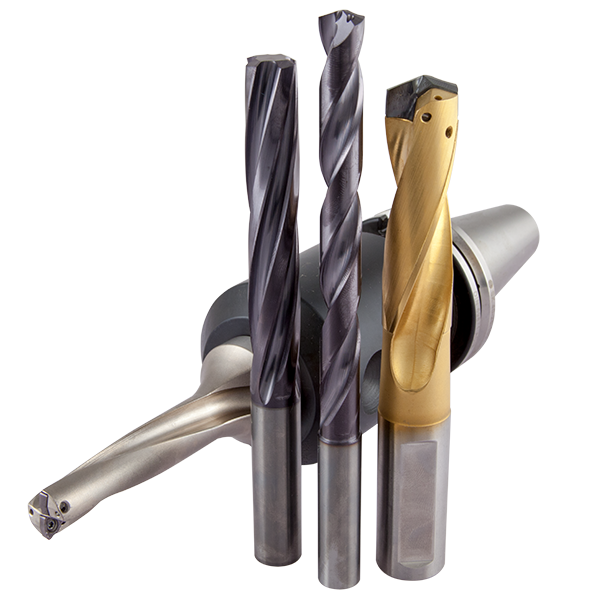

OBRÓBKA OTWORÓW

Oferujemy narzędzia do wiercenia i obróbki otworów, wiertła monolityczne wykonane z różnych materiałów (węglik spiekany, stal proszkowa, HSS/HSSCo) z zastosowaniem różnych powłok, wysokowydajne wiertła składane z wymiennymi płytkami KRUZ oraz z płytkami wieloostrzowymi i łopatkowymi.

GWINTOWANIE

Poza standardowymi gwintownikami polecamy wysokowydajne gwintowniki maszynowe, pozwalające na 2 lub nawet 3 razy szybszą obróbkę. Posiadamy gwintowniki odpowiednie dla każdej grupy materiałowej: P, M, S, K, H, N.

UCHWYTY

Posiadamy bogaty zbiór precyzyjnych uchwytów do narzędzi obrotowych. Proponujemy modułowy system uchwytów Infinity stosowany do obróbki na dużym wysięgu (możliwość obróbki <1000 mm). Pozwala on na obróbkę ciężko dostępnych miejsc.

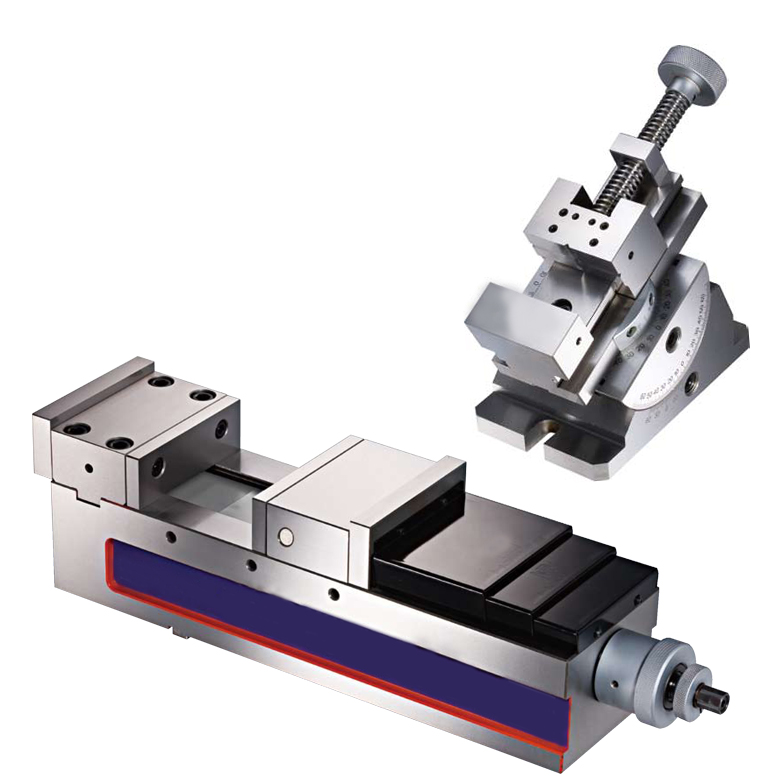

IMADŁA

Oferujemy imadła o najwyższej dokładności i powtarzalności, przystosowane do mocowania elementów w przestrzeni obrabiarek CNC. Przestrzeń roboczą obrabiarki można wykorzystać maksymalnie dzięki jej optymalnemu połączeniu z siłą zacisku.

Oferujemy:

- imadła samocentrujące

- imadła śrubowe (standardowe)

- imadła mechaniczne (siła zacisku do 8 ton)

- imadła pneumatyczne

- imadła dzielone

- imadła kątowe oraz obrotowe

- modułowe imadła LVF (sterowane CNC imadła obrotowe do produkcji wielkoseryjnej)

SYSTEMY MOCUJĄCE

Takie systemy tworzą serie elementów mocujących, które zostały wykonane z żeliwa oraz aluminium. Istnieje możliwość wykorzystania wielu detali w jednym zamocowaniu. Żeliwne korpusy tłumią drgania, zaś aluminiowe przeznaczone są do wykonywania wnęk dostosowanych do kształtu przedmiotów obrabianych. Umożliwiają maksymalne wykorzystanie przestrzeni roboczej obrabiarki, zapewniając stabilne i pewne zamocowanie.

Oferujemy następujące grupy:

- kolumny ustalające (do mocowania detali na obrabiarkach ze stołem obrotowym lub obrabiarkach wieloosiowych)

- płyty mocujące (stabilne mocowanie dużych elementów)

- elementy bazujące (łapy, dociski, itp.)

UCHWYTY WIELOSZCZĘKOWE

Uchwyty wieloszczękowe mocowane są na tokarkach oraz stołach obróbczych. W naszej ofercie występują uchwyty nastawne oraz samocentrujące. Wysoka precyzja oraz powtarzalność mocowania pozwala na bardzo dokładną obróbkę. Idealne do mocowania odlewów lub odkuwek.

Typy uchwytów:

- uchwyty hydrauliczne

- uchwyty pneumatyczne

- kły obrotowe, nastawne oraz samocentrujące

PRZECIĄGACZE

To narzędzia służące do obróbki wieloseryjnej. Wykorzystywane są do obróbki zębatek, przekładni, elementów tłokowych, wielowypustów, elementów używanych w przemyśle lotniczym oraz motoryzacyjnym. Narzędzia te wykazują się doskonałą jakością obrabianych detali oraz wysoką wydajnością procesu. Ponadto oferujemy szeroką gamę powłok ochronnych zwiększających żywotność oraz wydajność narzędzi.

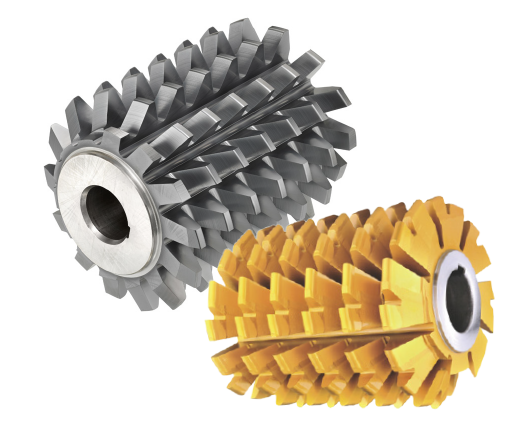

FREZY OBWIEDNIOWE

Wysokiej jakości frezy ślimakowe wykorzystywane są do obróbki zębów prostych oraz skośnych. Na życzenie klienta wykonujemy m.in. proturberancje, fazki oraz wszelkie modyfikacje zarysu zęba. Proponujemy następujące narzędzia: - frezy modułowe oraz podziałowe - frezy ślimakowe - wzorcowe koła zębate - dwuczęściowe frezy zgrubno-wykańczające

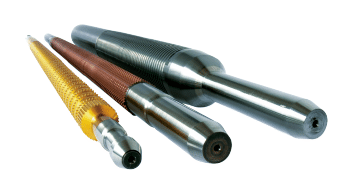

DŁUTAKI

W swojej ofercie posiadamy noże Fellows’a proste oraz skośne. To narzędzia do obróbki wszelkiego rodzaju wewnętrznych oraz zewnętrznych uzębień, zarysów ewolwentowych, przekładni łańcuchowych oraz śrubowych. Proponujemy także trzpienie ustalające, które są wykorzystywane do określenia średnicy podziałowej elementów wielowypustowych lub średnicy zasadniczej wewnętrznych wielowypustów lub zarysów ewolwentowych.

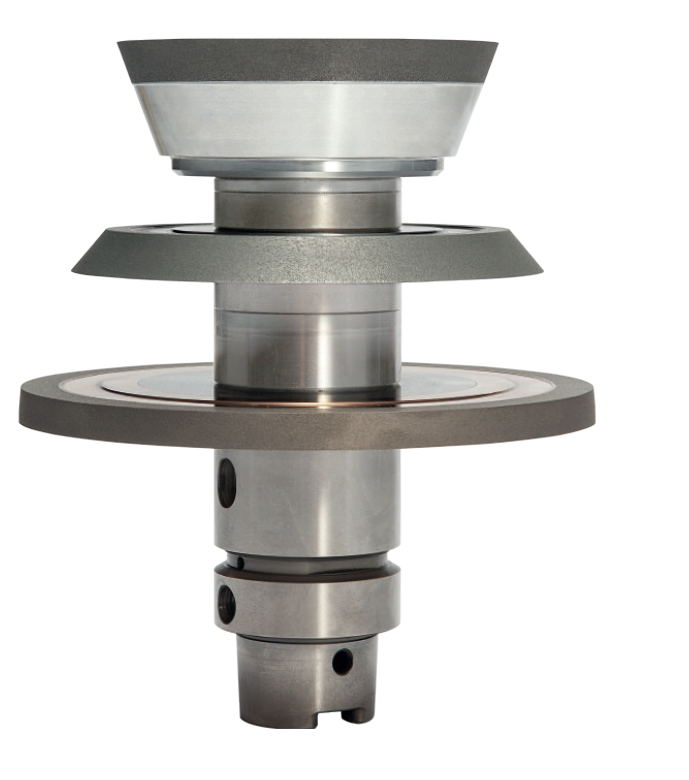

ŚCIERNICE

Oferujemy ściernice diamentowe oraz CBN. To optymalne rozwiązanie poprawiające jakość oraz produktywność szlifowania narzędzi skrawających, które przybierają różnorodne kształty oraz wykonane są z różnych materiałów. Bazując na naszym szerokim doświadczeniu w produkcji narzędzi, opracowaliśmy innowacyjne spoiwo w celu zwiększenia produktywności oraz jakości szlifowanych detali. Posiadamy serię tarcz szlifierskich wg ISO. Zachęcamy również do składania zamówień na tarcze specjalne.

PRĘTY WĘGLIKOWE

Oferujemy pręty węglikowe od ø1 do ø32, o długości 310 mm lub 330 mm. Istnieje możliwość docinania prętów na specjalne zamówienie. Oferujemy pręty szlifowane (tolerancja h6) oraz nieszlifowane. Pręty dostępne są w kilku gatunkach, o różnej wielkości ziarna (od 0,2 µm do kilku µm) oraz wskaźniku TRS od 2600 do 4500 [N/mm2]. Posiadamy pręty służące do obróbki ogólnej (gatunek ekonomiczny) oraz pręty najwyższej możliwej jakości, które są przystosowane do obróbki materiałów hartowanych oraz ciężko skrawalnych.

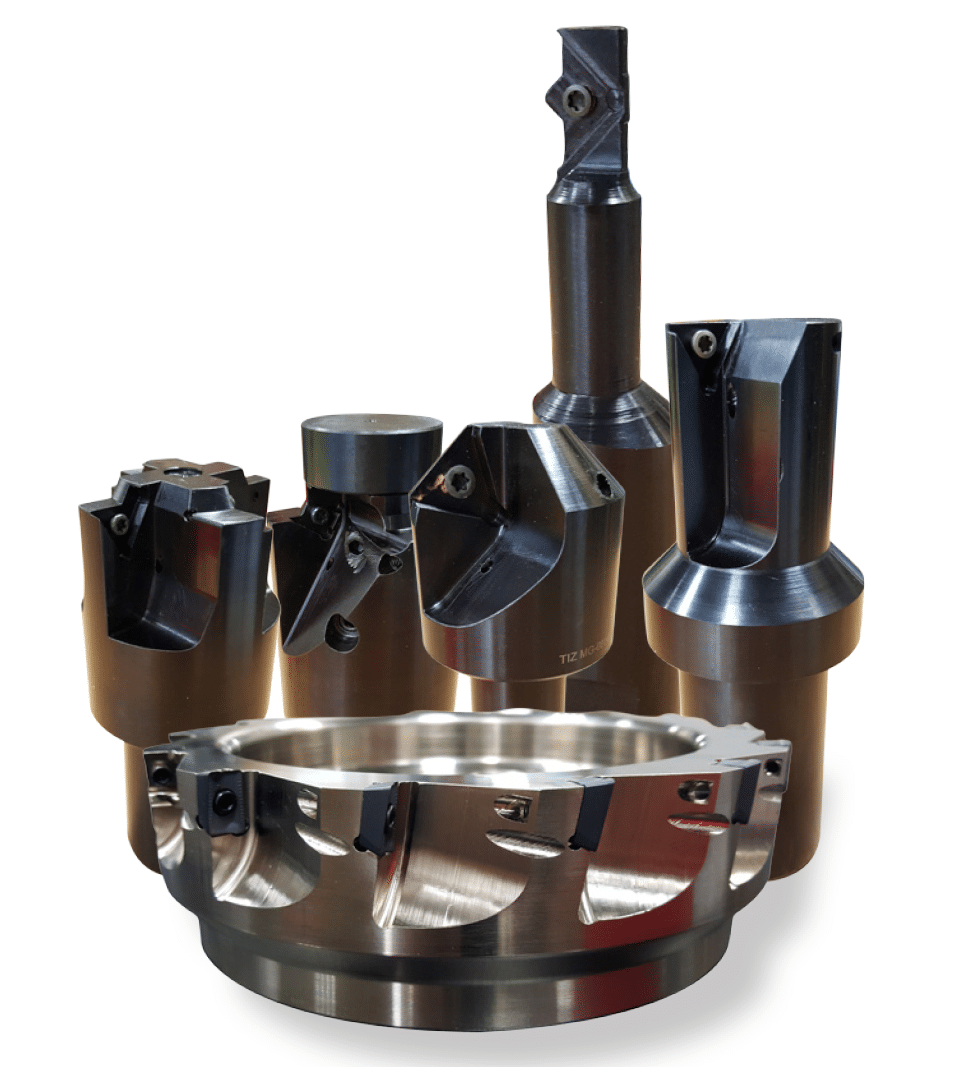

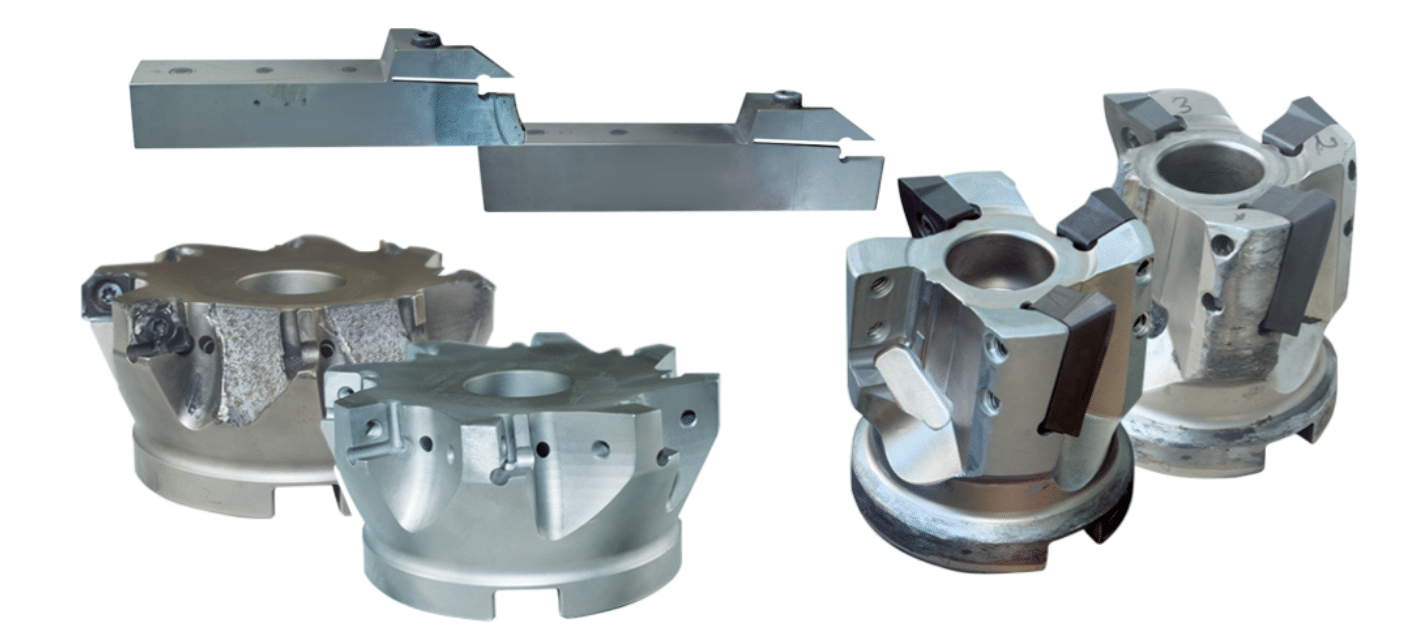

NARZĘDZIA MONOLITYCZNE, SKŁADANE ORAZ MONOBLOKI

Narzędzia specjalne wykorzystywane są podczas złożonych operacji. Umożliwiają zwiększenie produktywności oraz obróbkę elementów nietechnologicznych. To nietypowe rozwiązania dostosowane do indywidualnych wymagań klientów. Tę grupę tworzą narzędzia monolityczne, składane oraz tzw. monobloki (narzędzie wykonane z litego wałka – stożek bazowy i korpus narzędzia stanowią jeden element), które zapewniają maksymalną wydajność i jakość obróbki. Narzędzia specjalne dostępne m.in. w poniższych kategoriach: - wytaczadła (zgrubne, wykańczające) - wiertła (składane do 50xD, stopniowe) - narzędzia frezarskie - narzędzia tokarskie - narzędzia wielooperacyjne - uchwyty frezarskie - redukcje lub przedłużki - narzędzia antywibracyjne - narzędzia napędzane

ZREGENERUJ I OSZCZĘDŹ!

Jednym z ważniejszych założeń polityki TIZ Implements jest ochrona środowiska naturalnego. Firma wdraża tę politykę, realizując różnorodne działania, m.in. regenerując zużyte narzędzia skrawające. Wykorzystując tę metodę, TIZ Implements nie tylko chroni przyrodę, ale również obniża koszty gospodarki narzędziowej. Koszt regeneracji stanowi zaledwie 30-35% ceny nowego narzędzia! Opłaca się odnawiać również tańsze narzędzia, które oferują niemal wszystkie przedsiębiorstwa zajmujące się obróbką skrawaniem. Według naszych szacunków aż 80% naprawianych narzędzi stanowią właśnie te najpopularniejsze, których cena nie jest zbyt wysoka. Odnawiać można wszystkie narzędzia, niezależnie od producenta.

NA CZYM TO POLEGA?

Regeneracja polega na naprawie i odnowieniu narzędzi, dzięki czemu można je ponownie wykorzystać. W przeciwieństwie do popularnej usługi ostrzenia regeneracja nie jest metodą ubytkową. Odnowione narzędzia działają jak nowe – zachowuje te same parametry oraz przechodzą te same testy. Pierwotne właściwości mają nawet te narzędzia, które zostały poddane regeneracji trzykrotnie (w oryginalnych tolerancjach zostają zachowane krawędzie tnące; zmiana w obiciu osiowym/promieniowym jest minimalna; twardość oraz właściwości materiału pozostają zbliżone do oryginału). Naprawione narzędzia badane są pod kątem koncentryczności oraz prostoliniowości. Do klienta trafiają z certyfikatem zgodności z oryginałem.

JAKIE USZKODZENIA MOŻNA NAPRAWIĆ?

Metodą regeneracji można odnowić różnorodne narzędzia, które zostały uszkodzone podczas eksploatacji. TIZ Implements świadczy usługi polegające na odnowie: złamanych lub uszkodzonych krawędzi tnących/kieszeni, uszkodzonych gwintów, zapieczonych śrub. Ponadto firma naprawia uszkodzenia polegające na zużyciu mierzonym na średnicy skrawającej oraz zużyciu mierzonym od czoła narzędzia.

TIZ Implements ceni innowacyjne rozwiązania. Firma wychodzi naprzeciw oczekiwaniom klientów, dbając o czas i wygodę przedsiębiorców oraz jakość świadczonych przez nich usług. Aby osiągnąć te cele, TIZ Implements od lat inwestuje w najnowocześniejsze systemy oraz urządzenia. Dzięki temu wyróżnia się na rynku, a klienci darzą firmę zaufaniem.

SYSTEM B2B

W odpowiedzi na rosnące potrzeby klientów firma TIZ Implements zdecydowała się na wdrożenie sprawnie działającego systemu B2B. Platforma służy do kompleksowej obsługi klienta – upraszcza proces składania zamówień oraz ułatwia wyszukiwanie naszych narzędzi po ich cechach (wymiarach, zastosowaniu). Dzięki systemowi klienci mają również stały kontakt online z technologiem.

Dynamicznie zmieniające się otoczenie biznesowe, coraz większa liczba zleceń i projektów, potrzeba inwestowania w nowych pracowników, szybki rozwój technologii oraz konieczność zwiększania wydajności to ogromne wyzwania, z którymi muszą zmierzyć się wszystkie rozwijające się firmy. TIZ Implements wspiera przedsiębiorców, realizując usługę polegającą na outsourcingu. Taka współpraca pozwala na realne wsparcie strategii biznesowej klienta, optymalizację procesów i kosztów oraz wzrost innowacyjności.

To także profesjonalne wsparcie dla wyspecjalizowanej kadry, która podczas realizacji większej liczby zleceń lub nowych projektów jest bardziej obciążona, co może skutkować spadkiem efektywności i jakości wykonywanej pracy. TIZ Implemetns w celu kompletnego przygotowania procesu technologicznego wykonuje audyt stanu technologii danego przedsiębiorstwa. Obejmuje on przegląd rozwiązań maszynowych i programowych wykorzystywanych przez klienta. Audyt umożliwia również identyfikację problemów oraz dostosowanie infrastruktury do zmieniających się potrzeb biznesowych

JAKIE KORZYŚCI ODNOSZĄ FIRMY, KTÓRE WYBRAŁY KOMPLEKSOWY OUTSOURCING OFEROWANY PRZEZ TIZ IMPLEMENTS?

JAKIE KORZYŚCI ODNOSZĄ FIRMY, KTÓRE WYBRAŁY KOMPLEKSOWY OUTSOURCING OFEROWANY PRZEZ TIZ IMPLEMENTS?

- Wsparcie przy realizacji misji oraz osiąganiu celów strategicznych

- Usprawnienie procesów biznesowych

- Wzrost konkurencyjności firmy na rynku

- Wzrost efektywności firmy bez konieczności zatrudniania nowych pracowników

- Profesjonalne wsparcie dla wysoko wykwalifikowanej kadry technologicznej

- Możliwość korzystania ze sprawdzonych rozwiązań oraz doświadczonego personelu

- Brak potrzeby inwestowania w nowych pracowników

- Zaspokojenie tymczasowo wzmożonych potrzeb firmy podczas realizacji nowych oraz bieżących projektów

- Dokonanie płatności dopiero po udanym wdrożeniu rozwiązania technologicznego

PRZYGOTOWANIE POSTPROCESORÓW

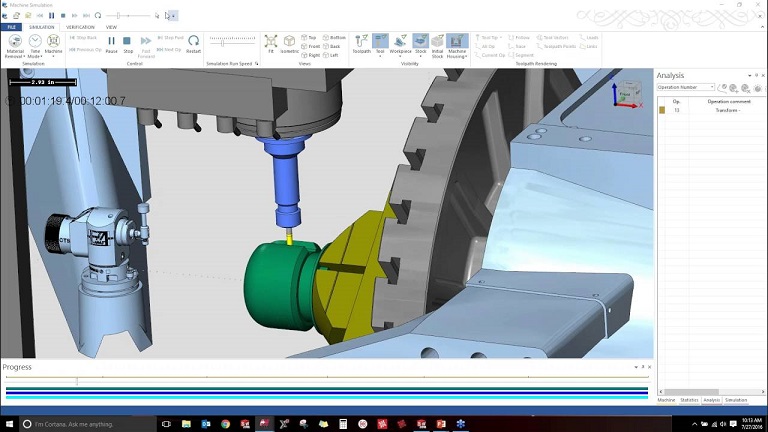

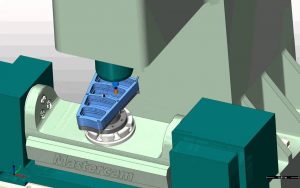

Każda maszyna sterowana numerycznie (CNC) wymaga odpowiedniego, zrozumiałego dla niej kodu NC (sekwencji poleceń). Postprocesor zapisuje odpowiedni kod na dysku w postaci pliku tekstowego oraz zapewnia jego poprawny format. Dla każdej obsługiwanej przez system CAM maszyny należy przygotować odpowiedni postprocesor. Poprawnie wykonany zapewnia bezpieczeństwo pracy maszyny oraz maksymalne wykorzystanie jej możliwości. Ponadto skraca czas, który należy poświęcić na testowanie wdrażanych detali oraz eliminuje ręczne poprawianie kodu NC. Obsługa profesjonalnie przygotowanego postprocesora nie wymaga wiedzy z zakresu działania i programowania maszyny. Wszelkie ustawienia wykonywane są w systemie CAM.

Jako alternatywę dla fizycznej weryfikacji obróbki i działania postprocesora na obrabiarce TIZ Implements oferuje opcję przygotowania w systemie CAM niezależnej symulacji pracy maszyny, tzw. maszyny wirtualnej. Umożliwia to przeprowadzenie symulacji kodu NC pochodzącego z postprocesora lub innego źródła.

USŁUGI W ZAKRESIE PRZYGOTOWANIA POSTPROCESORÓW

Firma TIZ Implements posiada wieloletnie doświadczenie w zakresie przygotowywania postprocesorów, symulacji pracy maszyny oraz wdrożeń popularnych systemów CAM. Klienci doceniają fachowość i profesjonalizm dostarczanych przez nas rozwiązań. Firma wspiera przedsiębiorstwa, które dopiero rozpoczęły działalność w obszarze obróbki na maszynach CNC, wyjaśniając wszelkie wątpliwości dotyczące oprogramowania maszyn lub wyboru sterowania. TIZ Implements współpracuje także z doświadczonymi użytkownikami. Na specjalne zamówienie takich klientów firma wyposaża postprocesory w zaawansowane opcje i funkcjonalności.

UŁATWIAMY PRACĘ NASZYM KLIENTOM I DAJEMY NIEOGRANICZONE MOŻLIWOŚCI

Dokładamy wszelkich starań, aby nasi klienci świadomie podejmowali decyzje. Każda osoba, która zgłosi się do TIZ Implements otrzyma fachową pomoc oraz wsparcie, ponieważ jako eksperci w dziedzinie obróbki skrawaniem zdajemy sobie sprawę z tego, jak bardzo kłopotliwy dla klientów może okazać się wybór właściwych narzędzi.

Duża liczba ofert na rynku i obszerne katalogi zawierające specyficzne nazewnictwo; brak czasu; konieczność precyzyjnego oszacowania kosztów i wreszcie dostosowanie oferty do rzeczywistych potrzeb danej firmy – to tylko niektóre problemy, z jakimi zmagają się osoby dokonujące zakupu narzędzi skrawających.

Po przeanalizowaniu potrzeb klientów i trudności, które napotykają, postanowiliśmy dodać do naszej oferty dwie wyróżniające nas na rynku usługi – szkolenia oraz systemy wspomagające. Dzięki nim osoby, które wybrały TIZ Implements, mają szansę zdobyć wiedzę oraz samodzielnie zawęzić wybór narzędzi, uwzględniając w pierwszej kolejności specyfikę swojej firmy. W ten sposób wspomagamy naszych klientów w drodze do celów, które sobie wyznaczyli.

Jakieś pytania?

Zadaj nam pytanie w formularzu. Odpowiemy niezwłocznie. Możesz również zapoznać się z działalnością naszej firmy na platformach wideo Youtube i Vimeo

Youtube

Vimeo